Double Shafts Mixer

Double shaft mixer is used for mixing materials continuously & uniformly. During the mixing, the material can be uniformly mixed with binder (liquid binder or powder binder is considered by user’s formula), after mixed, the blended material can be continuously sent to the conveyor, transmit to the next equipment. Double shaft mixer is usually applied to mix coal, mineral powder, iron powder, oxidation iron, coal slurry, sludge, clay, fly ash etc, with the good effect on mixing & blending.It is mainly used for wetting and mixing of fly ash in power plants, and also for chemical, chemical and other conveying equipment. Mining and other industries humidify, mix and transport solid particulate matter or powder.

Applicable raw materials

Double Shafts Mixer applicable raw materials

The applicable raw materials can be coal powders, lignite(wood coal) powders, peat coal, charcoal powders, brown coal, coke powders, aluminum dross, magnesium chips, quicklime powders, sludge, fertilizers and so on.

Structure

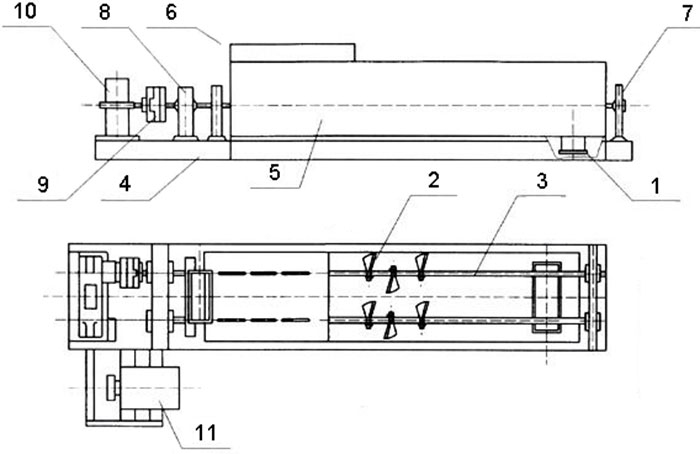

Double Shafts Mixer structure

2. Paddle

3. Shaft

4. Base

5. Chassis

6. Material input

8. Gearbox

9. Coupling

10. Reducer

11. Motor

Working principle

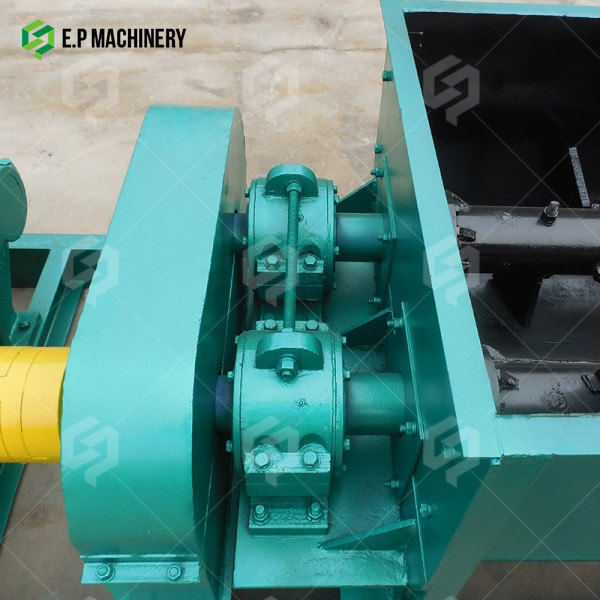

When the material enters the machine trough from the feed inlet, the two mixing shafts rotate in the horizontal cylinder in the opposite direction at the same speed, and then the specially arranged blades make the material move radially, circularly and axially at the same time, forming a complex cycle. The water spraying device immediately sprays water, making the material change from dry state to wet state. At the same time, the wet materials continuously mix with each other under the action of the spiral stirring blades and move towards the discharge port. Finally, qualified materials are discharged from the discharge port.

Double Shafts Mixer-one mixing shafts

Double Shafts Mixer-two mixing shafts

Advantages

1.The whole mixing and conveying process is carried out in closed space, without dust leakage, clean and environmental protection.

2.It integrates agitation, humidification and transportation. It has good mixing uniformity, high production efficiency and high productivity.

3.The mixing blade is made of wear-resistant material and treated by special surface treatment, so it has high wear resistance.

4.The whole machine has compact structure, small occupancy space, smooth transmission, high reliability and low noise.

Technical Parameter

| Model | Power | Capacity | Width | Weight | Size |

| HSJB-2500 | 7.5/11kw | 8~10t/h | 600mm | 1.8 ton | 3.5*1*0.75m |

| HSJB-3000 | 15/18.5kw | 10~15t/h | 800mm | 2.2 ton | 4*1*0.75m |

| HSJB-3500 | 11/22kw | 12~20t/h | 800mm | 2.4 ton | 4.5*1*0.75m |

| HSJB-4000 | 15kw | 15~25t/h | 800mm | 3 ton | 5*1*0.85m |