Tel: +8613633713237 +8613673361755

Iron ore powder briquetting machine is not only an innovative equipment for traditional metallurgy, but also a key technical node to achieve the "dual carbon" goal. As the global steel industry transforms towards short processes and low carbonization, the synergistic value of this equipment in aspects such as value-added utilization of mineral powder, clean transportation, and intelligent production will continue to be released, promoting green upgrades of the entire industry chain.

Need to process aluminum powder, aluminum ash and other metal waste? The single-unit capacity of large-volume aluminum powder briquetting machine is up to 30 tons/hour, 60-200MPa high-pressure molding, pellet density ≥2.0g/cm³, and low smelting loss! Intelligent PLC control saves 30% energy, wear-resistant mold life is 5000 hours+, dust spillage is ≤5mg/m³, and environmental protection meets standards. Suitable for metal recycling and smelting plants, customers have measured an annual revenue increase of more than 2 million yuan! Support free material pressure testing, customized ball diameter and production capacity solutions, click to get professional equipment quotes and technical consultation!

Discover affordable 5 ton/hour lime briquetting machine price from a leading small-scale lime powder briquetting machine manufacturer. Our durable lime briquette press ensures high output, low energy use, and factory-direct savings. Perfect for metallurgy, agriculture, and construction. Request a quote now!

[EP Quicklime Ball Press] China's professional manufacturer, high pressure forming technology helps steel mills and building materials industry reduce costs and increase efficiency! Customized design, ball density reaches 2.2g/cm³, factory direct sales with a 30% discount, 500+ corporate success cases verified. Free pressure test + technical solutions, consult now to get exclusive quotes!

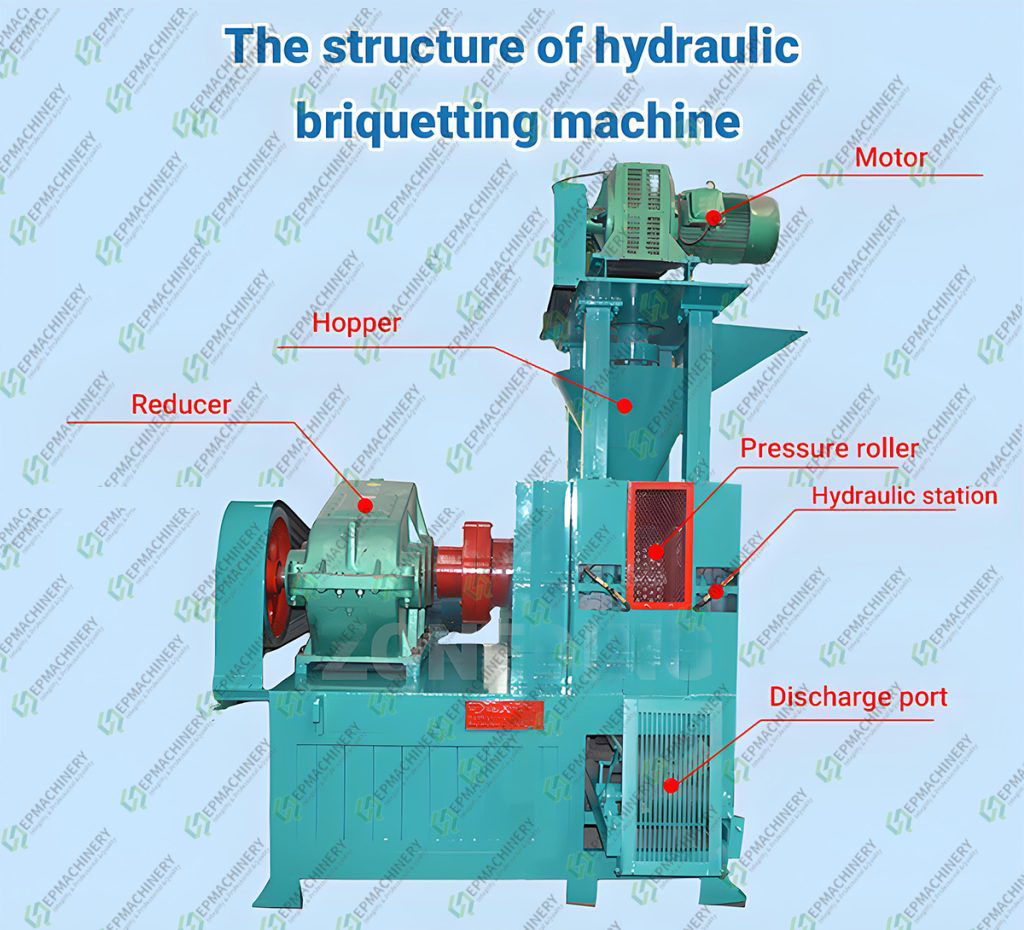

High-pressure roller briquetting machine is a device that compresses powdery or granular materials into briquettes through high pressure. It is widely used in metallurgy, chemical industry, building materials and other industries to improve the utilization rate of raw materials and save energy.