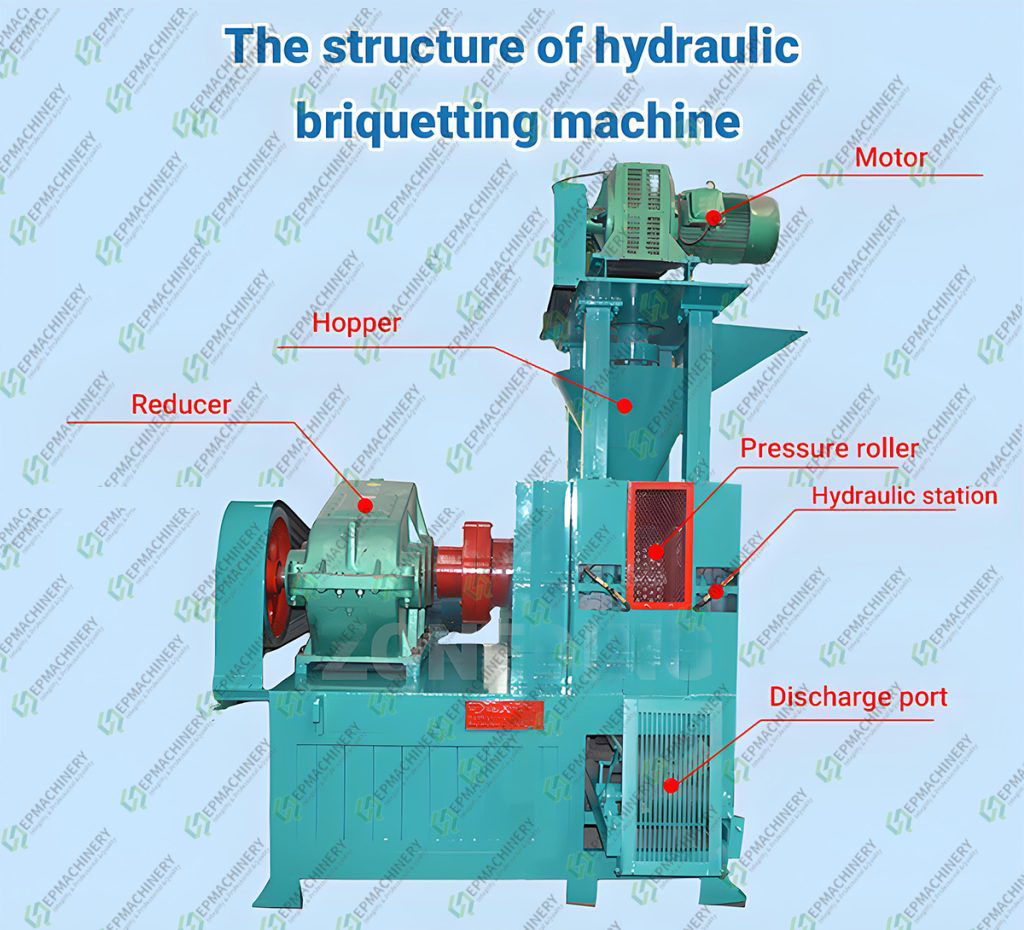

Hydraulic Roll Briquette Press

Hydraulic roll briquette press is a series of briquetting machine equipped with a complete set of hydraulic unit. This briquette machine is widely used to compress all kinds of mineral powder into dense briquettes, which with high strength and high density.

Hydraulic Roll Briquette Press Materials

Almost all the materials can be used in the Hydraulic Roll Briquette Press.

Hydraulic Roll Briquette Press Materials

the following are some common materials:

- Fuel: coal, charcoal, etc

- Metal: oxide scale, mill scale, iron, aluminum, ferro silicon, copper, chrome, chromite, manganese, nickel, zinc, etc

- Mineral: kaolin, laterite, magnesite, fluorite, fluorspar, silicon, dolomite, etc

- Other: lime, plaster, coke, carbon black, gypsum, clay, sludge, converter dust, pigment, etc

Although almost all materials can be used in Hydraulic Roll Briquettes Press Machine, each type of briquetting machine has its own specialties in terms of materials and briquetting. We recommend that you choose the right model based on your material and finished product density as well as your budget to maximize your benefits.

Requirement of raw material

Feeding Materials Condition: size less than 5mm, and moisture content requires 8-12%

Advantages

- 1.High density of final briquettes

With a hydraulic system, final briquettes density could be increased higher.

- 2.Higher pressure

Equipped with a hydraulic unit to increase working pressure during two rollers compression.

- 3.Adjustable working pressure

The machines pressure could be adjusted based on various materials powder, or special requests of final briquettes strength or density.

- 4.Overloading protection device of briquetting rolls

When fed into raw materials mixed with metal chips, or other hard materials, the hydraulic unit will enlarge chamber between two rollers to make sure hard materials get through, to protect not damage of rollers.

Technical specifications:

| Model | Capacity (T/H) | Power(KW) | Rollers Dia.(MM) | Weight(T) |

| HSYQH-290 | 3-4 | 7.5 | 290 | 1.5 |

| HSYQH-360 | 4-5 | 15/18.5 | 360 | 2.5 |

| HSYQH-400 | 5-6 | 15/18.5 | 400 | 2.8 |

| HSYQH-450 | 6-8 | 37 | 450 | 6.3 |

HSYQH-500 | 7-8 | 37-4/30-6 | 500 | 6.5 |

| HSYQH-520 | 8-10 | 55 | 520 | 11 |

| HSYQH-560 | 12-15 | 45-6 | 560 | 16 |

| HSYQH-650 | 15-18 | 45-6 | 650 | 17 |

| HSYQH-700 | 15-20 | 75-6 | 700 | 18 |

| HSYQH-750 | 20-22 | 55-6 | 750 | 23 |

| HSYQH-850 | 23-26 | 55-6 | 850 | 28 |

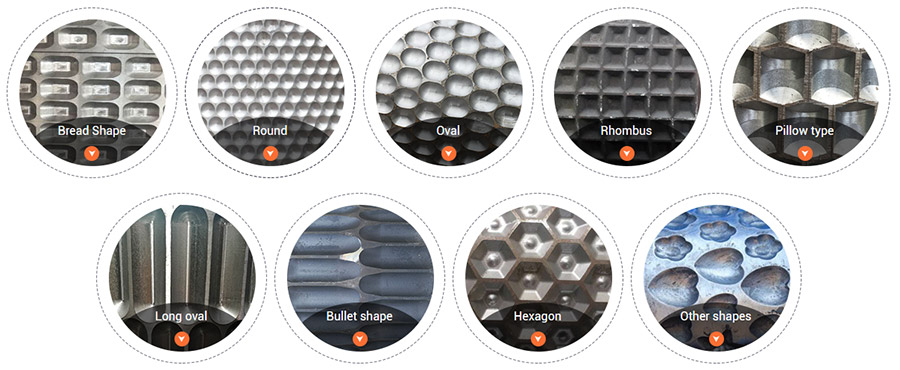

The briquette ball size

The size of the pressure ball can be customized according to customer requirements.

With further consideration of capacity and the briquette strength, our recommend size is between 25mm to 50mm.

The shapes of briquette

The shapes of briquette

The shapes of briquette can be all kinds of different shapes based on different molds, like square shape, spherical shape, oval shape, cylindrical shape, bread shape, pillow shape, etc. We can produce the special shapes based on customers’ demands.

Roller

Mold Can Be Customized

Usually, three types of roller materials are used, 65Mn, 9Cr2Mo, and stainless steel. 65Mn roller is a low-cost cast steel material with a service life of generally 10-12 months. 9Cr2Mo roller is a high chromium alloy material with higher cost and good wear resistance, with a service life of generally 1.5-2 years. Stainless steel material can generally be used for 3-4 years.

Other high standard roller materials are also acceptable according to your investment and the specific raw material you need to deal with.

Hydraulic Roll Briquetting Press Price:

It depends on the model you plan to use as well as the parts, for the parts, the most important here is the feeding structure and the roller type.