- 1.Charcoal Briquetting Machine and Its Importance

- 2.Application of Charcoal Balls

- 3.Getting Charcoal/Coal Materials

- 4.Technology and working principle of charcoal briquetting machine

- 5.Different types of pelletizing machines and their working mechanisms

- 6.Get quotes and purchase guides for charcoal briquette equipment

Charcoal Briquetting Machine and Its Importance

Charcoal Briquetting Machine compresses loose charcoal powder into blocks under high pressure, which is convenient for transportation and improves combustion efficiency.

Application of Charcoal Balls

As a multifunctional material, charcoal balls play an important role in many industries.

First of all, in the energy field, it is widely used as a fuel in barbecue, heating and industrial production processes. Because it generates high heat and low pollution when burned, it has become an ideal substitute for traditional fuels.

In addition, charcoal balls also have important applications in agriculture. They can be used as soil conditioners to help improve soil structure and increase fertility.

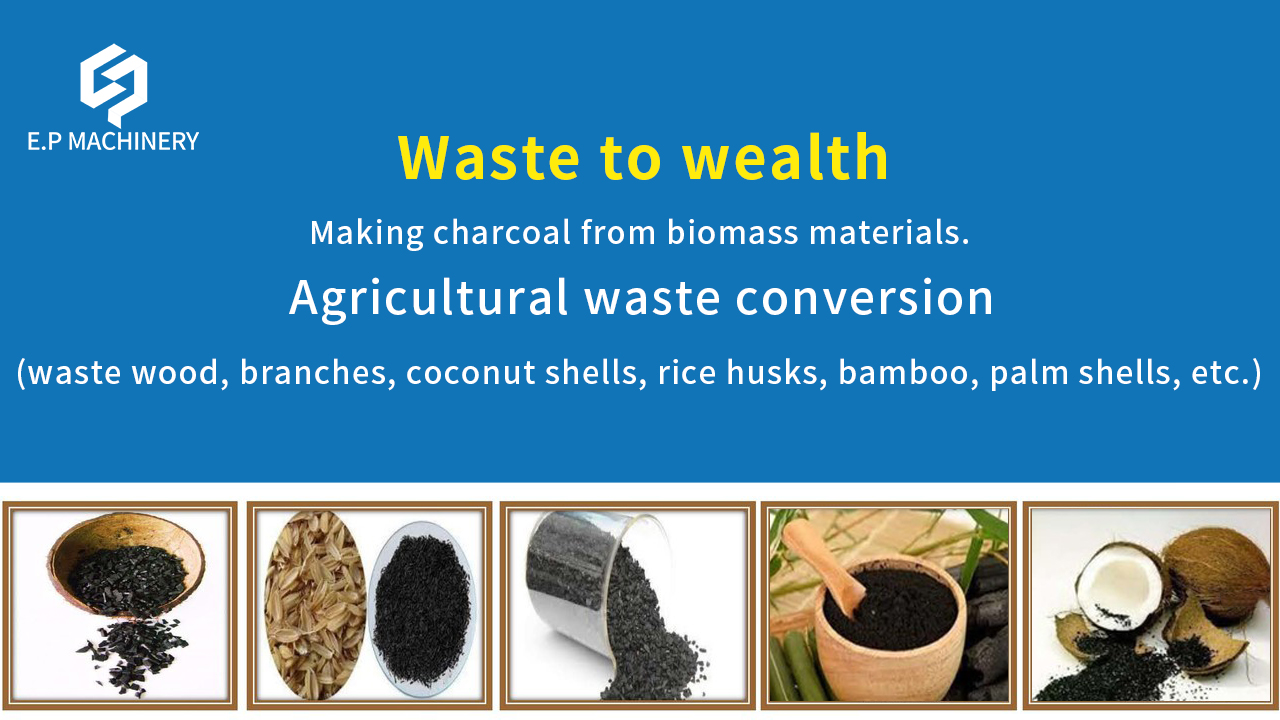

Getting Charcoal/Coal Materials

Waste charcoal or coal dust. In charcoal production plants or coal mines, there are a large number of small pieces of waste charcoal or coal dust. These waste charcoals can be collected and used to make honeycomb briquettes. This is not only a good way to obtain cheap honeycomb briquettes raw materials, but also can turn waste into treasure and improve resource utilization.

Use biomass materials to make charcoal, such as waste wood, branches, coconut shells, rice husks, bamboo, palm shells, etc. You need to build a charcoal kiln to produce charcoal, or use a carbonization furnace to carbonize biomass materials into charcoal.

Technology and working principle of charcoal briquetting machine

As an advanced mechanical equipment, the core value of charcoal briquetting machine is reflected in the efficient extrusion process. This machine can compress the raw materials through precise technology and reasonable configuration to form charcoal blocks with tight structure and regular shape.

In terms of operation method, it is usually necessary to follow the equipment instructions to ensure that each link can be accurately controlled to ensure the quality of the final product. During the extrusion process, various parameters of the machine such as pressure and temperature need to be precisely controlled to ensure that the density and combustion performance of the charcoal blocks are optimized.

Different types of pelletizing machines and their working mechanisms

In the field of pelletizing machinery, different machine types show different characteristics and application ranges according to their unique technical parameters and working principles.

Charcoal briquette extruder, also named as charcoal briquette forming machine. It uses the principle of screw extrusion to extrude the charcoal powder, coal powder, carbon powder, and other powdery materials mixed with adhesives, making them into round shape, hexagonal shape or other different shapes briquettes with high strength.

Charcoal Briquette Extruder Machine

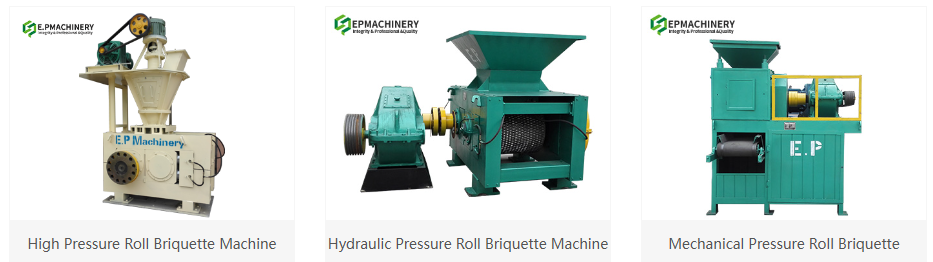

Pillow charcoal machines are widely used in the production of various specifications of charcoal rods due to their stable molding pressure and high production efficiency;

Here are 3 types of pillow briquette machines. According to the different pressures, we divide them into mechanical pressing, high pressure, and hydraulic roller briquetting machines.

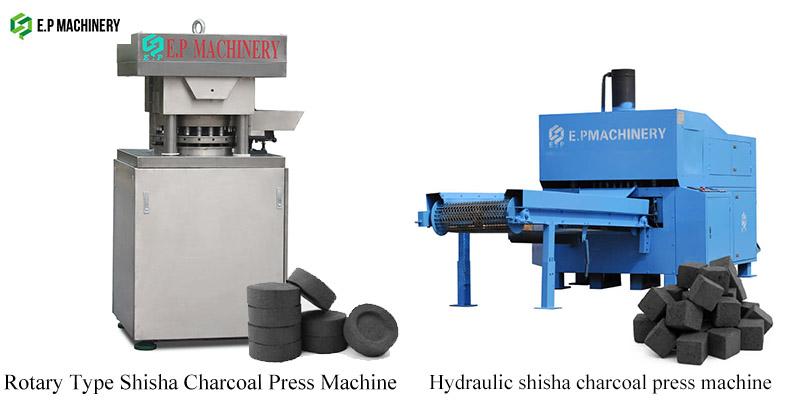

Hookah charcoal machines are particularly suitable for the production of high-quality hookah charcoal due to their fine hookah production process and strict requirements for raw materials;

Here are 2 types of shisha charcoal machines

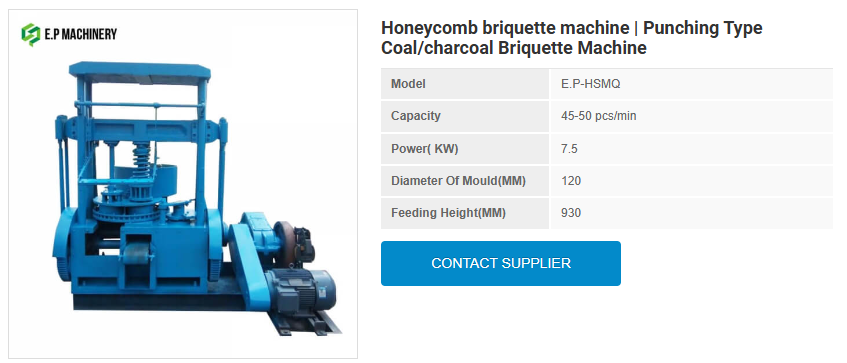

Honeycomb briquette machines are particularly suitable for home heating and small industrial boilers because they can press out honeycomb structures with good ventilation.

Honeycomb briquette machine | Punching Type Coal/charcoal Briquette Machine

Get quotes and purchase guides for charcoal briquette equipment

When considering investing in charcoal briquette equipment, obtaining accurate market price information is a key first step.

You can obtain this information by visiting professional industrial equipment websites or contacting manufacturers directly.

When evaluating different quotes, in addition to the price itself, you should also carefully consider factors such as the quality of the equipment, brand reputation, and after-sales service.

Although high-quality equipment has a large initial investment, it can save you more operating costs in the long run due to low maintenance costs and low failure rates.

In addition, good after-sales service ensures that problems with the equipment can be quickly and effectively resolved, reducing the risk of production delays.

Therefore, considering these factors will help you make a more informed decision when choosing a charcoal briquette machine.