Tel: +8613633713237 +8613673361755

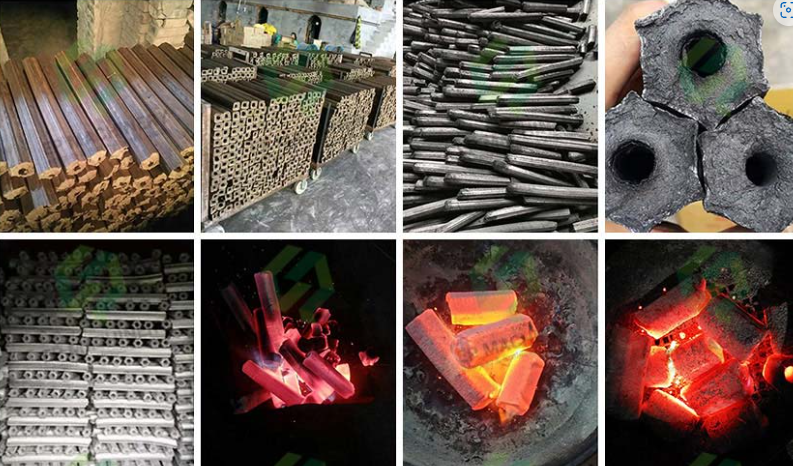

Biomass is widely extensive on the earth, everywhere will produce a lot of biomass waste day by day, deal with these materials in a good way not only helps to reduce the environmental pollution but also makes value from the raw materials. Now let’s follow the article to set up your own charcoal briquette plant with biomass an easy way.

The metallized sludge briquette is a normal way to deal with the waste sludge in steel plant. With metallize way almost all the sludge can be recycled meanwhile non-ferrous metals can be removed (zinc, lead), the removed rate for zinc oxide can be more than 90%.

Make sludge briquette as slagging flux and coolant is the commonest way of dealing with sludge by the steel manufacturers. The raw materials of sludge briquette are the byproducts of the steelmaking process – sludge and mill scale, add some binder will form these materials to briquette.

1 What is aluminum dross briquette 2 Why make aluminum dross briquette 3 The aluminum dross sources 4 Make aluminum dross as a flux modifier 5 Aluminum dross briquette press machine 6 Process of aluminum dross flux briquette making 7 Things should pay attention to improve your briquetting work