As one of the important machine in the mineral to metal process, briquette machine has done a lot of work to make use the mineral dust.

Contents

Why make mineral briquette

Directly use mineral dust will make lots of waste of the raw material as well as the energy cost, thus briquette them and use the briquette in furnace become a good way to solve the problem.

Common minerals

Iron ore powder (hematite, magnetite, limonite, etc.), Manganese Ore, Chromium ore (chromite massive Isometric, chrompicotite, etc.), Silica ( quartz, tridymite, cristobalite, etc.), Bauxite, Fluorite, Magnesite, Dolomite, Limestone, Quicklime, Bentonite, Copper ore ( sulphide copper ore, oxidized copper ore, etc. ), Nickel ( sulphide ore, oxidized ore ), Lead ore concentrate, Zink ore concentrate, Tin ore concentrate, etc.

Common minerals

Important things on the briquette process(Mineral Size,Moisture,Pressure,Binder)

1.Moisture

By choosing the different briquette presses with different pressure and briquette size, you will need to find the most suitable moisture for making your briquette. Generally located between 3 and 15%. Normally, low pressure should be with high moisture, and also, high pressure with low moisture.

2.Pressure

Not high pressure will help you to make a high quality briquette. Actually, a pressure too high will break the structure of the mineral powders and make the briquette with low strength.

3.Binder

Minerals are hard to briquette as it’s of low plasticity, we need high pressure and a well-distributed binder to do this work. Mix the mineral powder with binder will help you to make high quality briquette, note, different mineral powders need to use different mixers to get a better mix effect.

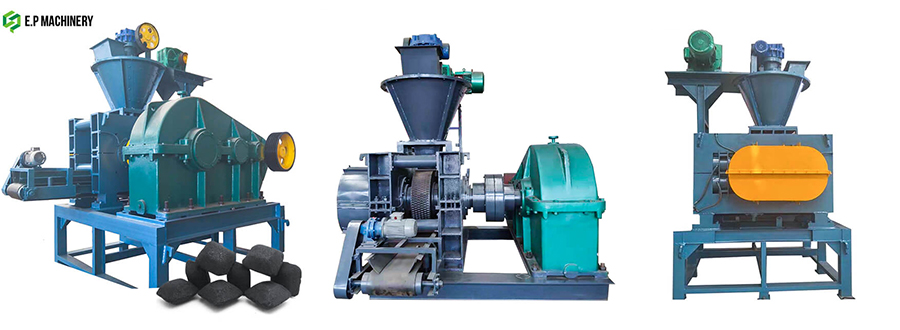

Use High Pressure Roll Briquette Machine to make mineral briquette

The advantage of using roller briquette press to make mineral briquette.

Continuous running

E.P briquette machine is designed based on fatigue strength and 24-hour continuous run. Lubrication system, overall structural strength and components assembling precision can ensure continuous working.

Longer lifespan

E.P briquette machine is made from qualified steels, the key parts are made from special alloy steels and advanced heat-treated to ensure lifespan.

High pressure

E.P briquette machine has high assembling precision, run stably, low noise.

Easy maintenance

E.P briquette machine is made from high-quality steels, high rigidity, high assembling precision and high pressure without vibration.

High rate of briquette forming

E.P briquette machine adopts reasonable layout and compact structure, which is convenient for disassembly and assembly to reduce operation and maintenance cost.

Environmental-friendly

Due to the E.P briquette machine has advantages of high pressure, high manufacturing and assembling precision, so the resulting briquettes are with high forming rate, high strength and not easy to be disintegrated.

The Briquette

Mineral briquette machine for sale

Use a High Pressure Roll Briquette Machine will help to briquette some of the mineral powders with low moisture.

High Pressure Roll Briquette Machine

The Advantages

- A dry process: raw material granulated with low moisture, not requiring drying.

- A simple technology: fast implementation, ease of maintenance, easy handling.

- An efficient process: cheaper granules with reduced fixed costs and low production cost.

- Less wear than classical die presses.

- A flexible process. A large range of clays (bentonite, sepiolite, attapulgite…) can be granulated on our roller presses.