Tel: +8613633713237 +8613673361755

Coal briquette's uses range from households to industries, from local consumption to global trade, covering multiple dimensions of energy demand. It not only solves the pollution problem of traditional loose coal, but also continues to expand application scenarios through technological innovation and policy support. Whether it is reducing corporate costs, improving residents' lives, or promoting sustainable development, coal briquettes have demonstrated strong market potential and social value.

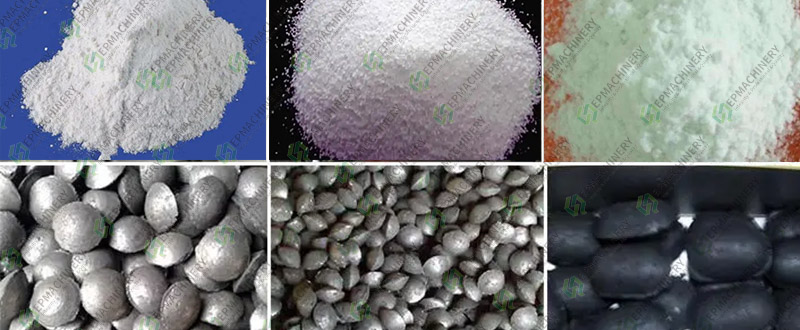

Professionally customized small aluminum powder briquetting machine solves the problem of recycling aluminum chips and waste aluminum powder! Using 20-60MPa high-pressure molding and anti-oxidation mold technology, aluminum powder and aluminum slag are efficiently compressed into high-density pellets, increasing the recovery rate by more than 30%, saving more than $120,000 per year. Suitable for metal recycling, 3D printing and export needs, energy saving of 40%, and investment payback period of less than 6 months. Get a customized solution now and start a new chapter of green recycling!

In today’s fast-paced industrial landscape, managing waste materials like lime powder efficiently has become a critical challenge. For industries dealing with lime byproducts containing less than 10% moisture content, the industrial lime powder briquetting machine offers a game-changing solution. This article dives into the innovative high-density lime pellet briquetting press technology, its workflow, and how it transforms low-value lime dust into premium, reusable pellets—boosting profitability while promoting sustainability.

EP Machinery analyzes the production process of blast furnace flux pellets: The quicklime briquette machine presses the powder into high-strength pellets, reducing the coke ratio by 8%-12%, saving more than 10 million yuan in costs annually! Adapting to steel slag and dust removal ash processing, providing direct sales and technical solutions for metallurgical briquette machine manufacturers, helping steel mills reduce costs and increase efficiency. Consult now to obtain case data!

Coal binders play an important role in the coal briquetting process and directly affect the quality and performance of coal briquettes. This article summarizes the types of coal briquette binders, the effects of adhesives on coal briquette performance, and the ratio of coal powder binders. I hope it can help you find the binder that best suits your coal briquettes.