Coal binder plays a vital role in the process of coal briquetting, which directly affects the quality and performance of coal balls.

What are the types of coal ball binders?

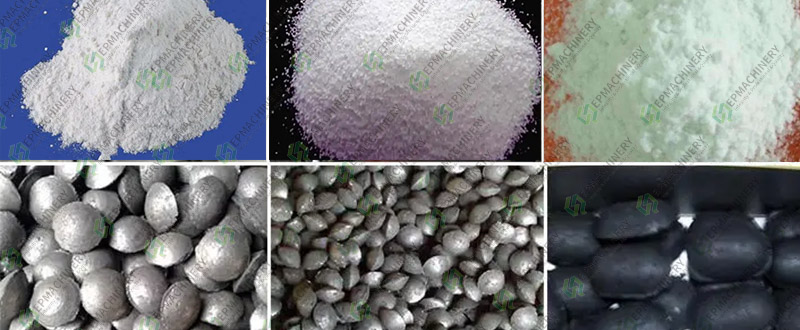

Coal ball binders are substances that bind raw materials such as coal powder together to make them into shapes. There are three main types: inorganic binders, organic binders and composite binders.

Inorganic binders

Clays: bentonite, kaolin

Cement: ordinary silicate cement, slag cement

Organic binders

Starches: corn starch, sweet potato starch, cassava starch

Cellulose: carboxymethyl cellulose (CMC), hydroxypropyl methyl cellulose (HPMC)

Resins: phenolic resin, urea-formaldehyde resin

Composite binders

Composite binders are two or more different types of binders mixed to give full play to their respective advantages.

For example, the inorganic binder bentonite and the organic binder corn starch are mixed in a certain proportion, so that the coal balls have both good strength (provided by starch) and can maintain shape stability during combustion (provided by bentonite).

This composite binder is increasingly used in actual briquette production, and the formula can be adjusted according to the specific coal quality and briquette usage requirements.

Effect of adhesives on briquettes performance

- Organic binders have good bonding properties and high strength of finished briquettes, but the thermal strength and thermal stability of briquettes are poor, and some binders have poor water resistance.

- Inorganic binders are widely available and low in cost. Briquettes have good thermal strength and thermal stability, but they will increase the ash content of briquettes and reduce calorific value.

- The complementary properties of materials mixed with composite adhesives are the development direction of binders.

Ratio of coal powder binder

How to make the best briquette? The amount of binder plays a vital role in the quality of briquette.

Generally, the more binder is added to the coal powder, the higher the strength of the briquette.

However, in order to reduce the cost of the briquette plant, the amount of binder added should be lower as long as the quality of the briquette is qualified.

The ratio of binder will vary according to factors such as the type of coal (such as anthracite, bituminous coal, etc.), the purpose of the briquette (civilian, industrial), and the production process (such as cold pressing, hot pressing). In actual production, it needs to be adjusted and optimized according to the specific situation.

- Bentonite: Bentonite is a commonly used binder in the production of some small-scale civilian coal balls. The general amount of binder is about 3% - 5%; in industrial coal briquettes, the amount of bentonite added is increased to 5% - 10%

- Ordinary Portland cement: It is used in the production of some industrial coal briquettes that require higher strength, generally within 10%.

- Kaolin: It is widely used in the production of industrial coal briquettes, usually depending on the nature of the coal and the purpose of the briquettes, about 2% - 8%.

- Corn starch: It is generally widely used in the production of civilian clean coal briquettes (occasions with high environmental protection requirements), and the amount of binder is generally 5% - 10%.

- Sweet potato starch: Similar to corn starch, but it has a wide source and a lower price. However, the stability of sweet potato starch may be slightly worse, and the strength of the coal briquettes may be affected in a humid environment. The proportion of binder is usually around 6% - 12%.

- Carboxymethyl cellulose (CMC): It is easily soluble in water and has good thickening and bonding properties. In the production of coal balls, CMC can significantly improve the bonding strength of coal balls and improve the waterproof performance of coal balls. In the production of industrial coal balls, especially for some coal balls that need to be transported over long distances or stored in humid environments, adding CMC can effectively prevent the coal balls from breaking, and the addition amount is generally 1% - 3%.

- Phenolic resin: It has high bonding strength and thermal stability, but the price is relatively high. It is generally used in industrial fields with extremely high requirements for the quality of coal balls, such as coal balls for metallurgy. The proportion of adhesive is about 3% - 8%.

- Urea-formaldehyde resin: It has good bonding performance, and its performance can be controlled by adjusting the ratio of urea and formaldehyde. In the production of coal balls, urea-formaldehyde resin can cure quickly to shape coal balls, and the amount of adhesive is generally 2% - 6%.

- Composite binder: This composite binder is increasingly widely used in the actual production of coal balls, and the formula can be adjusted according to the specific coal quality and coal ball use requirements.

For example, when bentonite and corn starch are used in combination, when the proportion of bentonite is 2% - 6% and corn starch is 3% - 9%, the compressive strength of the briquettes can reach 3 - 7MPa. This composite binder can comprehensively play the advantages of bentonite's structural stability and corn starch's good formability, making the strength performance of briquettes more balanced.