Mechanical Pressure Roll Briquette Machine

Mechanical Pressure Roll Briquette Machine is a device that uses mechanical pressure to press raw materials into blocks. It can be applied to various materials to limit their pressure, and it usually requires the use of some adhesive or water to complete the compaction.

Materials

Mechanical Pressure Roll Briquette Machine materials

Almost all the materials can be used in the Mechanical Pressure Roll Briquette Machine, the following are some common materials:

- Fuel: coal, charcoal, etc

- Metal: oxide scale, mill scale, iron, aluminum, ferro silicon, copper, chrome, chromite, manganese, nickel, zinc, etc

- Mineral: kaolin, laterite, magnesite, fluorite, fluorspar, silicon, dolomite, etc

- Other: lime, plaster, coke, carbon black, gypsum, clay, sludge, converter dust, pigment, etc

Requirement of raw material

Size

High quality briquette comes from the small raw material, for common materials, less than 5mm is a good choice for energy saving and usage.

Moisture

Moisture is very important in briquetting process, if the material is too wet, it will stick in the roller hole and the machine won’t make briquette anymore, too dry, you can’t even get the shaped briquette.

So, what is the proper moisture for briquetting?

This is different from material to material, and also have something to do with the binder you plan to use.

Here is an example:

In coal briquette making process, when using lime and clay as binder, the moisture should be between 16-18%, but when use pulp or sodium humate as binder, the moisture requirement change into 10%, if the binder is asphalt, the moisture even low to 2-4%!

A binder mixed briquetting process

In the roller briquette press process, the materials need to add binder before briquetting, we have different consideration for the binders, for example, if your material is too wet to briquette, we usually need to dry it, but if the moisture is not that high, we solve the problem by adding some dry binder not only for briquetting also for moisture controlling. The proportion of binder is different for different materials.

Another important thing for binder

Usually we choose binder which cost less and is easy to get, herewith some common binders which may be very suitable for you to get and use. starch, syrup, cement, etc.

The briquette ball size

Size can be between 10mm to 110mm.

With further consideration of capacity and the briquette strength, our recommend size is between 25mm to 50mm.

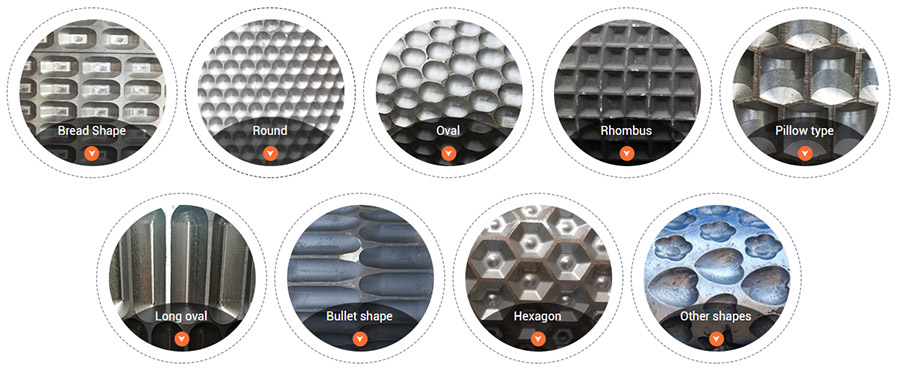

The shapes of briquette

The shapes of briquette

The finished briquettes can be all kinds of different shapes based on different molds, like square shape, spherical shape, oval shape, cylindrical shape, bread shape, pillow shape, etc. Above are some common shapes for this kind of briquette machine, we also manufacture some other special shape according to what you need.

Roller

Mechanical Pressure Briquette mold Can Be Customized

Two kinds of roller materials are usually used, 65Mn and 9Cr2Mo. The 65Mn roller is a kind of steel castings material with low cost and the 9Cr2Mo roller is high chromium alloy material which cost more but with higher wear resistance.

All of the two rollers are treated with our special heat treatment to make it with high wear resistance. For different briquette materials, you should choose roller by your condition. Generally, the 65Mn roller is used in small briquette machine with soft material, such as coal, charcoal, carbon, etc. And the 9Cr2Mo roller is usually used in the big briquette machine with materials such as mineral, iron powder, laterite, etc.

Other high standard roller materials are also acceptable according to your investment and the specific raw material you need to deal with.

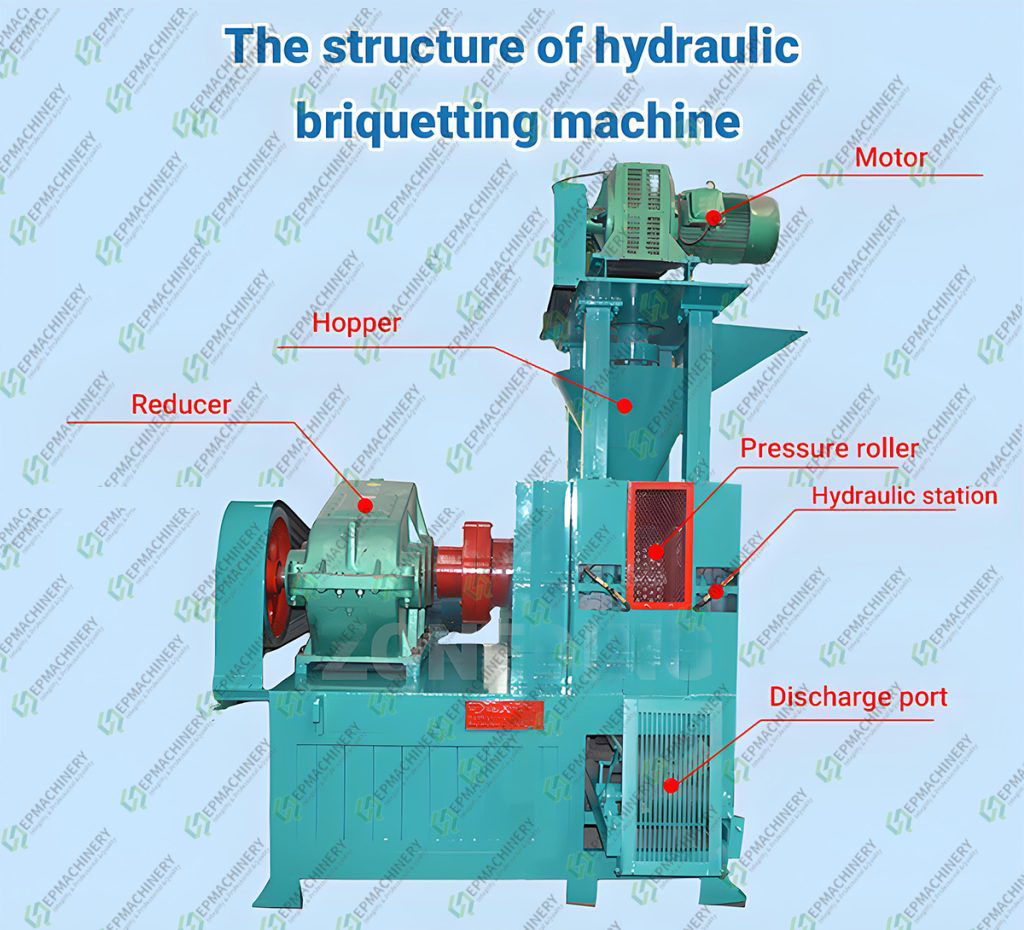

Mechanical Pressure Briquette Machine working principle

In order to compact powders into briquettes, the raw materials need to be pre-compacted firstly, and then transported to briquette machine for compacting. There are three steps of briquetting.

- Pre-compacting: pre-compacting raw materials by pre-compacting machine.

- Compacting: pre-compacted raw materials flow into the two rollers of briquette machine, up to the highest pressure between two rollers.

- Discharging: after compacting, the cavities will be separated gradually, with the rotation of the two rollers. The briquettes will be discharged from the cavities under its centrifugal force and gravity.

Note:

Along the width direction of the rollers, the center briquettes are denser than the briquettes on both sides of the rollers, because the compacting conditions are different. This is normal.

In practical production, it is normal for the briquettes with 3mm briquette edge.

According to the specific raw material, when the roller speed matches with the pre-compacting speed, the rate of briquette forming will be the best. Please find and set up the point in practical production.

Mechanical Pressure Briquette Machine application:

- Metallurgical industry. The fine of non-ferrous metals and ferrous metals can be briquette and re-smelting, such as laterite nickel ore, alum ore, manganese ore, furnace dust, steel slag, mineral waste residue, carbon black, copper powder, magnesium, alumina, iron ore concentrate, manganese ore, etc.

- Coal fuel briquette making. Making coal briquettes from coal fines, coke powder, slime, and midding coal, etc, the briquettes are used in industrial boilers and civil furnaces.

- Thermal power plant. Use the desulfurization gypsum making briquette as cement retarder.

- Chemical fertilizer industry. using coal dust to make briquette, instead of using lump coal, saving energy cost.

- Building materials industry. The ceramic factory, glass factory and the coal- gas generator, using coal fine briquette replace the lump coal for energy cost saving.

- Refractory industry. Making refractory briquette.

- Every kind of industry with powder material which should be briquette and then used in the kiln.

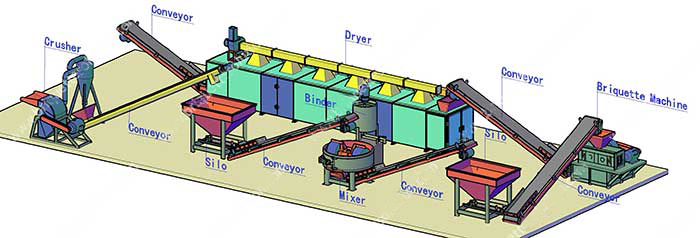

Mechanical Pressure Briquette Machine plant

Mechanical pressure briquette machine plant

Crusher: If your material is too big, generally, a crusher must be needed, or else that will reduce the working life of the roller. Furthermore get proper size material is also a way to make well binder mixed material;

Silo: Silo is used to store the material for a smooth feeding for the next step;

Mixer: A good binder mixed material will get a high strength briquette as well as the briquette shaping rate. The water (if needed) and binder will be added here;

Dryer: You can choose vertical dryer or belt dryer according to your budget, if you have time and place to dry the briquette, you can even remove this equipment.