Quicklime briquette machine is used to press quicklime powder into briquettes

Quicklime roll briquette press will compact into solid briquettes

Contents of this article

Introduction of Quicklime Powder

Quicklime or burnt lime, chemically known as calcium oxide (CaO), is a product made from limestone. Although mineral limestone can be used directly, its use is very limited. Most directly used limestone is used in the construction industry, and if it is ground to powder, steel mills will use it as a sintering material.

Making limestone into quicklime will greatly increase the usage. For example, steel plants will use quicklime as a slagging component (40-50 kilograms of quicklime per ton of steel), and calcium carbide plants will use quicklime as a raw material for producing calcium carbide (producing one ton of calcium carbide requires almost the same weight of quicklime).

So, there lay a lot of kilns for manufacturing quicklime. But in the process of limestone to quicklime, also there along produces a lot of dust quicklime. Usually, we may find them here:

- 1、Around the kiln;

- 2、The storage place;

- 3、In the transportation process;

- 4、Quicklime fine from the screen;

- 5、In dust collect process;

About 10% to 30% of the quicklime we can obtain is in powder form. "They can be sold as waste at a much lower price than lump quicklime, but they may be valuable if we turn them into coal.".

Benefits of using quicklime to compact blocks

- 1.A protection to the natural resources by decreasing the requirement of limestone;

- 2.Save energy and reduce greenhouse gas emissions.

- 3.Save money by reducing the quicklime’s material cost;

- 4.Minimize or eliminate quicklime dust

- 5.Improve the storage house environment.

- 6.Prevent lime less than 10mm going in the converter.

hydraulic roller briquette press run on a quicklime briquette plant

Quicklime powder molding machine

Quicklime reacts chemically with water, due to its good plasticity, we do not need to add water to the briquette and press it directly through the briquette press.

High Pressure Roll Briquette Machine is the commonest lime briquetting machine ever used. After the quick lime form to briquette through the machine, it can reach a density around 1.9-2.2 g/cm3.

It is a very good briquette machine to press the quicklime with a continuous work and produce briquette with high strength.

The working process of the briquette press

The working process of the briquette press

The raw material is fed to the hopper of the briquette machine and fed by the pre-press force feeding screw to the mid-gap of the rollers, the double counter-rotating roller compress the raw quicklime into solid quicklime briquettes, in this process, the press become higher and higher when the raw quicklime press from the top to the center of the rollers, and it reaches the maximum pressure at the center, after that, the pressure then becomes lower and lower until the briquette comes out from the rollers.

Quicklime molding process - the process of establishing a quicklime molding factory

- Most of the quicklime we get are from the two processes

- Screen process

- Dust collect process

In order to make use of the quicklime, the produced quicklime will go through a screen and leave the tiny ones. The size left behind normally is less than 5mm. The dust full of quicklime from the dust collector is less than 1mm.

To make these two small particle quicklime to briquette and also ensure the briquette quality, A rate for these materials is then chosen. Well distributed particles sizes will make the briquette with better quality.

The process

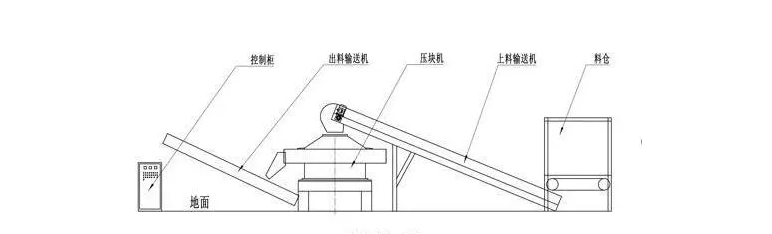

Collected quicklime (include quicklime from dust collector and screen quicklime fine from kiln) ⇒ silo ⇒ briquette ⇒ screen the briquette

The briquette process follows a way rapid and easy. In order to prevent the dust pollution, especially transport the quicklime from the dust collector, using pneumatic conveyor is best conveying way can be ever chosen.