Why do we need quicklime briquettes?

Quicklime, as an important industrial raw material, plays a vital role in various fields. Whether in steel smelting, building materials, or environmental protection, quicklime plays an irreplaceable role. However, due to its special physical properties, such as easy moisture absorption and easy reaction with carbon dioxide in the air, quicklime has many inconveniences during transportation and storage. Therefore, in order to improve the transportation efficiency of quicklime and reduce its loss during storage and use, briquetting has become a necessary means. Through briquetting, the performance and economic value of quicklime can be greatly improved, making it more effective in industrial production.

What are the quicklime briquetting equipments?

The process of quicklime briquetting requires a series of professional machines and equipment.

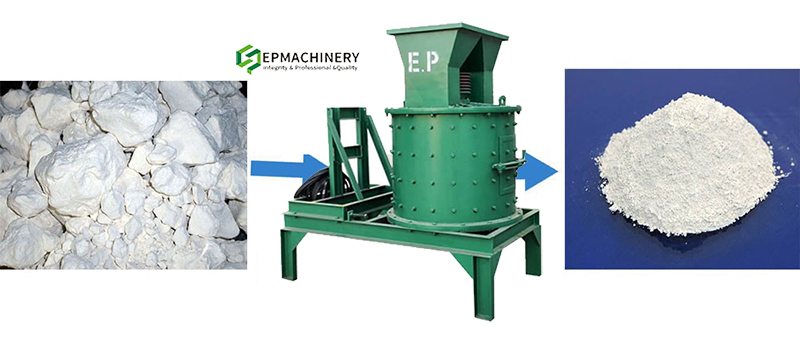

The first is the quicklime powder making machine, which grinds quicklime and converts it into fine quicklime powder.

Next is the mixer, which is used to evenly mix quicklime powder and other additives to prepare the ground for the subsequent briquetting process.

Then there is the quicklime briquetting machine, which is the key equipment in the entire process. It uses high pressure to compress the mixed quicklime powder into blocks of fixed shapes and sizes.

Quick Lime Roll Briquette Machine

Finally, there is the dryer, which removes moisture from the briquettes, ensuring their quality and storage life.

This series of equipment cooperates with each other to form a complete production line, which not only improves production efficiency but also ensures product quality. During operation, it is also necessary to strictly abide by operating procedures and perform regular maintenance and inspection of equipment to ensure the stability and safety of the production process.

Key technologies and issues that need attention during the lime briquetting process.

Quicklime briquetting is a technical activity, and its key steps include selecting high-quality quicklime, adjusting the appropriate humidity, pressure control, and subsequent maintenance.

1. The quality of the selected quicklime directly affects the effect of briquetting, so quicklime with high purity and good activity must be selected.

2. Adjust the humidity to an appropriate ratio. Too wet or too dry will affect the briquetting effect and the activity of quicklime.

3. Pressure control is also very critical. Excessive pressure may cause the briquette to be too dense, affecting subsequent use; too little pressure may cause the briquette structure to be unstable.

4. Carry out appropriate post-maintenance after the briquetting is completed to ensure uniform drying inside and outside the briquetting to prevent cracks.

During the entire process, special attention must be paid to the safety of operators to prevent quicklime from causing damage to the skin and respiratory tract. By accurately mastering the above technical points, high-quality quicklime briquettes can be efficiently produced.

Case study of quicklime briquetting

In the industrial field, the application of quicklime is ubiquitous. It is widely used in key fields such as steel smelting, sugar refining, and chemical industry and plays an important role.

The use of quicklime in steel smelting. Quicklime is added to the steelmaking furnace as part of the charge. At high temperatures, it reacts with impurities in the furnace, effectively removing these impurities and improving the quality of the steel.

Quicklime also plays an important role in the sugar making process. When refining sugar cane juice, quicklime can effectively extract the sugar, making it purer and improving the quality and taste of the sugar.

The role of quicklime in chemical industry production cannot be ignored. It is a key raw material for the production of bleaching powder, dyes and other products. In the production process of these products, the role of quicklime cannot be replaced, and its importance is self-evident.

In general, the important role of quicklime in industry cannot be ignored. Whether in steel smelting, sugar refining or chemical production, quicklime plays an irreplaceable role, and its contribution is indispensable to the entire industrial production.

Future development trends and potential markets of quicklime briquettes.

Quick lime briquetting technology, as a new environmentally friendly technology, its future development prospects are undoubtedly bright. In the future, we can foresee that quicklime briquetting technology will play an important role in many fields such as building materials, chemical industry, and metallurgy.

Come to us to learn quicklime briquetting technology

If you are interested in quicklime briquetting technology, please feel free to contact us. We have an experienced technical team that can provide you with a full range of solutions from raw material selection, production process, to later storage and sales.