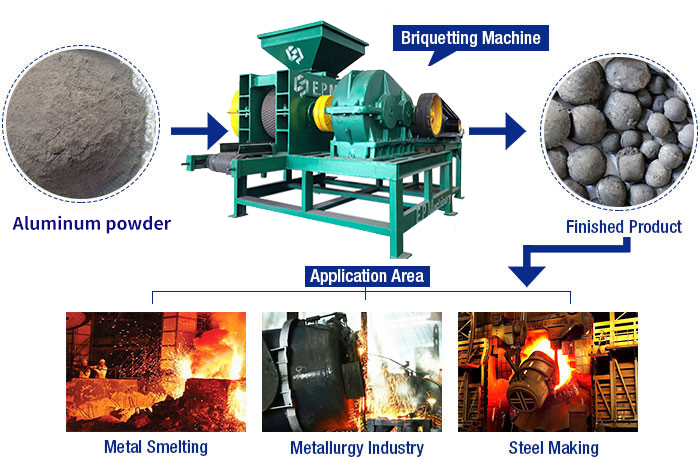

In modern industrial production, aluminum powder briquetting machines play an important role. Its working principle is to press aluminum powder into spheres of a certain shape and size through high pressure to facilitate further processing and use. The emergence of aluminum powder briquetting machines has greatly improved production efficiency, reduced labor input, and also reduced production costs. In addition, it also plays a key role in various application scenarios, such as metallurgy, mining, chemical industry and other fields. In these industries, aluminum powder briquetting machines can not only improve the utilization rate of raw materials, but also improve product quality and product performance. Therefore, the aluminum powder briquetting machine is an essential piece of equipment, both from an economic and environmental perspective.

1. The working principle, design advantages, technical parameters and performance characteristics of the aluminum powder briquetting machine.

1.1 Working principle of aluminum powder briquetting machine

1.2 Design advantages of aluminum powder briquetting machine

1.3 Technical parameters and performance characteristics of aluminum powder briquetting machine

2. Analysis of application examples of aluminum powder briquetting machine

3. Evaluation of aluminum powder briquetting machine by professional institutions and experts and scholars

4. Market prospects and development trends of aluminum powder briquetting machines

5. How to choose a suitable aluminum powder briquetting machine

1. The working principle, design advantages, technical parameters and performance characteristics of the aluminum powder briquetting machine.

1.1 Working principle of aluminum powder briquetting machine

Aluminum powder briquetting machine, as the name suggests, is a device that compresses aluminum powder into spherical shapes. Its working principle is mainly to use high-intensity pressure to squeeze the aluminum powder particles together tightly in the mold, thereby forming aluminum balls with a certain shape and size. The design features of this equipment are mainly reflected in the following aspects:

1.2 Design advantages of aluminum powder briquetting machine

First of all, the aluminum powder briquetting machine uses an advanced hydraulic system to make the pressure more stable and ensure the compaction effect of aluminum powder. Secondly, the equipment's operation panel is designed to be very user-friendly, allowing the operator to easily grasp the operating status of the equipment. Thirdly, the equipment also has a highly automated control system, which can realize automated production and greatly improve production efficiency.

1.3 Technical parameters and performance characteristics of aluminum powder briquetting machine

In terms of technical parameters, the working pressure, working speed and product size of the aluminum powder briquetting machine can be adjusted according to actual needs to meet the needs of different users. In terms of performance characteristics, the equipment not only has a compact structure and a small footprint, but also has stable operation, easy maintenance, and long service life. In general, the aluminum powder briquetting machine provides an efficient and convenient solution for aluminum powder processing with its excellent design features and excellent performance characteristics. Contact us for specific technical specifications.

2. Analysis of application examples of aluminum powder briquetting machine

As a key equipment in industry, aluminum powder briquetting machine has a wide range of applications, covering many different industries. For example, in the metallurgical industry, it is used to press aluminum powder into spherical shapes for further processing, greatly improving production efficiency and product purity. In the energy field, aluminum powder balls can be used as fuel additives to provide more energy for combustion and reduce harmful emissions. At the same time, aluminum powder pressed balls also play an important role in the chemical industry, serving as a catalyst or reaction material form to accelerate the chemical reaction process and improve output quality. In addition, some special industries such as fireworks manufacturing also use this technology to produce safer products. It is not difficult to see from these examples that the aluminum powder briquetting machine not only improves the use of raw materials, but also brings significant economic and environmental benefits to all walks of life.

3. Evaluation of aluminum powder briquetting machine by professional institutions and experts and scholars

In terms of professional evaluation of aluminum powder briquetting machines, many authoritative institutions and industry experts have spoken highly of it. According to a report issued by the International Nonferrous Metals Association, aluminum powder briquetting machines have significant advantages in energy conservation, emission reduction, and improvement of production efficiency, and are key equipment to promote technological progress in the aluminum industry. At the same time, the Organization for Economic Cooperation and Development (OECD) also emphasized the importance of this technology in sustainable industrial development. Professor Zhang, a well-known materials engineer, mentioned in his latest paper that the high efficiency and precision of the aluminum powder briquetting machine has set a new standard for the quality control of aluminum products. Its research results have not only promoted scientific research progress in related fields, but also It has a non-negligible impact on improving the competitiveness of the entire industry. Through the evaluations of these professional institutions and scholars, it is not difficult to see the great significance of the technological innovation of aluminum powder briquette machines to the development of modern industry.

4. Market prospects and development trends of aluminum powder briquetting machines

In the current market environment, the application of aluminum powder briquetting machines is becoming more and more widespread. This is due to its high compression efficiency and stable performance, which makes it occupy an important position in many industrial fields. Especially in the fields of metallurgy and chemical industry, aluminum powder briquetting machines have become indispensable equipment.

With the continuous development of technology, future aluminum powder briquetting machines are expected to achieve more efficient briquetting effects, while reducing energy consumption and improving environmental protection. This requires us to continue to innovate in technology research and development and constantly promote the technological upgrading of aluminum powder briquetting machines. In addition, with the popularization of emerging technologies such as big data and cloud computing, the intelligence of aluminum powder briquetting machines will also become a possibility. Through data analysis, we can control the ball pressing process more accurately and further improve the ball pressing efficiency.

In general, the aluminum powder briquetting machine has a very broad market prospect and huge potential for future development. We have reason to believe that through continuous technological innovation and optimization, aluminum powder briquettes will occupy a more important position in the future market.

5. How to choose a suitable aluminum powder briquetting machine

To choose a suitable aluminum powder briquetting machine, you should first clarify your own needs. This includes aspects such as expected production volume, requirements for finished product quality, and budget. For large-scale production users, it may be necessary to choose a large-scale briquetting machine to meet production needs; while for small-scale or experimental production, small-scale equipment may be more suitable. Secondly, the quality and performance of the equipment are also factors that must be considered when choosing. High-quality equipment not only ensures production efficiency, but also reduces failure rates, thereby reducing the time and cost of repairing and replacing equipment. In addition, after-sales service is also a factor that cannot be ignored. Good after-sales service can provide timely and effective support when equipment problems occur to avoid affecting the production process. Finally, price is an aspect that cannot be ignored when choosing equipment, but it is not a decisive factor. Reasonable budget planning and cost-effective comparison can help users find the equipment that best meets their needs and economic conditions. In general, choosing a suitable aluminum powder briquetting machine requires comprehensive consideration of various needs and conditions to achieve optimal production and economic benefits.

Aluminum powder briquetting machine is an important equipment in modern industry. It improves production efficiency and saves labor costs through precise pressure control and automated operation. It can also improve product quality, enhance market competitiveness, and play a key role in industrial development and efficiency improvement.