Biomass is widely extensive on the earth, everywhere will produce a lot of biomass waste day by day, deal with these materials in a good way not only helps to reduce the environmental pollution but also makes value from the raw materials. Now let’s follow the article to set up your own charcoal briquette plant with biomass an easy way.

Contents

Common biomass

The biomass waste includes a lot of materials, and there is a list of some common biomass materials:

- 1.different argo fibers like wheat straw, rice straw, rice husk, hay, jute stick, groundnut shell, energy grasses (miscanthus, elephant grass, switchgrass), seed husks, corn cobs, corn stover, energy cane, sugar cane bagasse, mustard stalk, coir pith, etc;

- 2.cotton stalk, bamboo, grapevine clippings, fruit tree clippings, coffee shrubs;

- 3.olive pits, coffee husk, peanut shells, and all other types of nut shells;

- 4.tobacco waste, used coffee grinds, dried tomato vines;

- 5.recycled paper, cardboard, spent bank notes;

- 6.dried animal droppings, dried sludge from wastewater treatment plants.

biomass materials

The biomass waste can be directly used to make biomass briquette by using different kinds of briquette machines, and there’s also another to make value from biomass by turning it to briquette.

Find a better way to make charcoal briquette

Compare to biomass briquette, charcoal has a bigger market in the usage of BBQ, cooking and others. Use charcoal briquette machine can directly use charcoal dust as raw material and find varies of briquette machines making different shapes of charcoal briquette for the market, that’s really an easy way. But these briquettes, as they are manufactured by briquetting, after we get the briquette, there’s still a problem lays in front of us as these briquettes have a high moisture content, find a way dry these briquettes cost lots of energy, or in some wonderful places with good sunshine, a very big place is also needed by drying these briquettes in the sunshine.

A process of making charcoal briquette without drying

Thus we need a better way to make charcoal briquette by using biomass without the final drying process. A way flexible with very low investment.

The briquette making process follows these steps and brings perfect briquette.

Raw Biomass ⇒ Crush ⇒ (Dry) ⇒ Briquette ⇒ Carbonize ⇒ Charcoal Briquette

1. Raw Biomass

Raw biomass should be collected first, you may store them in the workshop to avoid raw biomass turn too wet or polluted by the wind with stones or sands.

2. Crush

In order to get a proper size for briquetting and with high efficiency in the drying process, crush these materials is a good choice for briquette making. These small particle materials also improve the quality of the final briquette with more dense.

3. Dry

Keep the material dried by a hot air flow dryer is an effective way and easy to operate with normal fuels like coal and argo waste. The small particle biomass immediately goes through the dryer from the feeding hopper to the output. Other dryers like rotary drum dryer may be needed if you are planning to run a big factory for charcoal briquette making.

4. Briquette

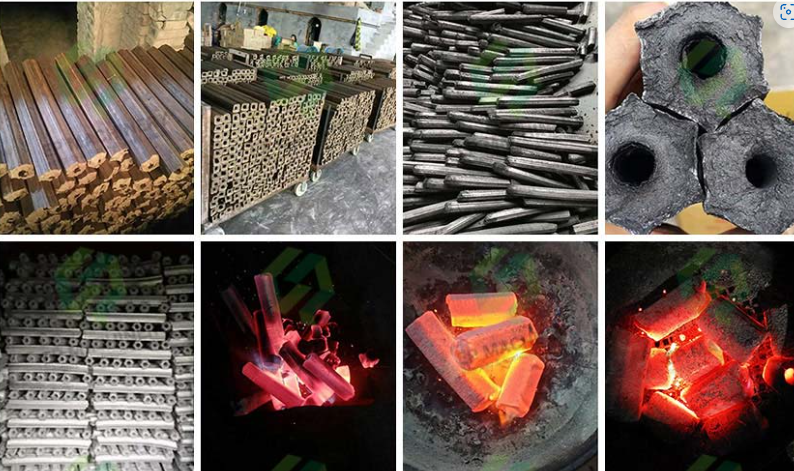

Choose the screw bio briquettes machine definitely helps to make biomass briquette most suitable for charcoal briquette making. The briquette (with a hole in the center) makes the inside carbonize more efficiency. The machine is at a reasonable price that affordable for even very small facility beginners to start the charcoal plant.

5. Carbonize

Carbonize the biomass by the carbonization furnace is a good and flexible choice. This machine works with a smoke clean system to prevent pollution to the atmosphere. The collected wood tar and wood vinegar help to make more value from the system. Self-built carbonization kiln is also another way to this process though that needs more space and investment..

6. Charcoal briquette

After carbonization, finally we get the charcoal briquette. These stick shape briquettes are easy to handle and packed in the cartoons. The density is higher than the briquette produced from the charcoal dust.

There are many ways to set up a charcoal briquette plant, this is a way easy to follow and with low investment. These briquettes with high density lead a longer burning time. The machines in the lines are all easy to operate and maintain. Even these short in investment can handle the line.