In the industrial field, fluorite is an important non-metallic mineral raw material, widely used in chemical industry, metallurgy, building materials and other industries. For better storage and transportation, fluorspar needs to be briquetted. Today, we will learn how to use a briquetting machine to briquet fluorite.

First, we need to conduct preliminary processing of fluorite. The excavated fluorite block material is crushed into a particle size suitable for briquetting through a crusher. The crushed fluorspar is then screened using screening equipment, such as a vibrating screen, to ensure a uniform particle size.

Use a Vertical crusher to crush fluorite lump materials into particles suitable for briquetting.

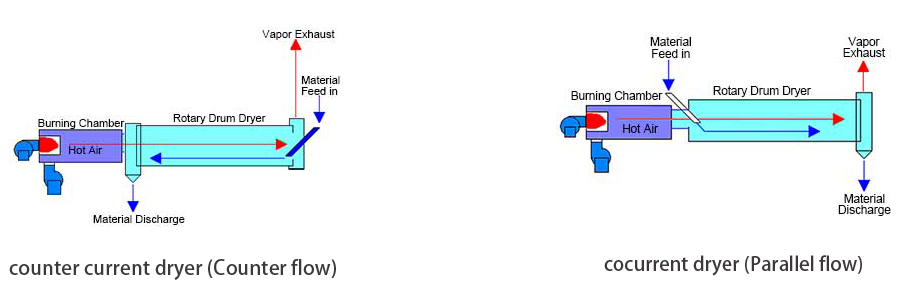

Next, we need to dry the fluorite. Since fluorite contains a certain amount of moisture, in order to ensure the quality of the briquettes, it must be dried. Usually we use a rotary dryer to evaporate the water through high-temperature hot air, so that the fluorite reaches a suitable humidity for briquetting.

Use a rotary dryer to dry fluorite particles

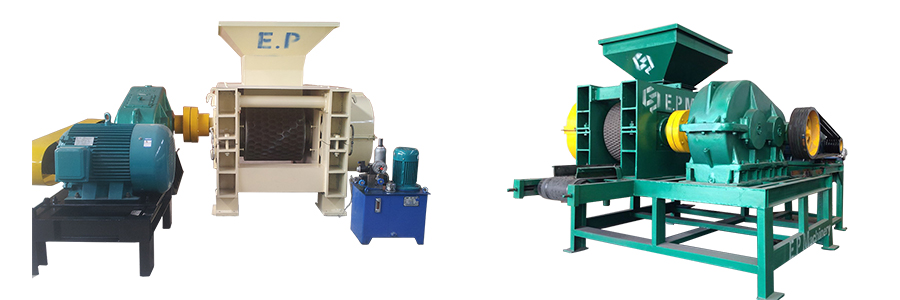

Next is the formal briquetting process. We use professional briquetting machines, such as hydraulic briquetting machines. This machine uses powerful hydraulic force to press bulk fluorite into blocks. During this process, attention needs to be paid to controlling the pressure. Excessive pressure may cause the fluorite to be crushed, and too little pressure may fail to compact the fluorite.

Next is the formal briquetting process. We use professional briquetting machines, such as hydraulic briquetting machines. This machine uses powerful hydraulic force to press bulk fluorite into blocks. During this process, attention needs to be paid to controlling the pressure. Excessive pressure may cause the fluorite to be crushed, and too little pressure may fail to compact the fluorite.

During the briquetting process, we can also add an appropriate amount of adhesive to increase the strength of the fluorite blocks. Commonly used adhesives include cement, gypsum, etc. However, it should be noted that the amount of binder added should be moderate, as too much binder will affect the purity of fluorite.

After completing the briquetting, we need to cool it down. This is because the temperature of the newly pressed fluorite blocks is relatively high. If it is packaged or stored directly without cooling, the packaging bag may be damaged or spontaneous combustion may occur during storage due to excessive temperature. Therefore, we need to place the pressed fluorite blocks in a well-ventilated place and let them cool naturally.

Once the fluorite blocks have cooled to room temperature, they are ready for packaging and storage. We usually use plastic bags or other well-sealed packaging materials for packaging to prevent the fluorite from getting damp. At the same time, the storage location should be a dry and ventilated place to prevent fluorite from getting damp or other contamination.

The above is the specific operation process of fluorspar briquetting using a briquetting machine. Each step requires careful operation to ensure that the final fluorspar block quality meets the standard. I hope this article can help you better understand and master the briquetting operation of fluorite.

From crushing, screening, drying to briquetting, cooling to final packaging and storage, every step is crucial, and every operation will affect the final quality of fluorspar. Therefore, we must be rigorous and meticulous in the operation process and cannot be sloppy in the slightest. Only in this way can we ensure that the fluorite blocks we obtain have good quality and performance and meet the needs of industrial production.

This is all about the specific operating procedures of the fluorite briquetting machine. If you have any other questions about this, please leave a message in the comment area and we will be happy to answer it for you.