Gypsum briquette machine is used to briquette gypsum to make it with shapes like ball, pillow. etc. Most of the gypsum used are the desulfurization gypsum, so it is always called as desulfurization, gypsum briquette machine is for this wide usage. Besides, another common usage, gypsum briquetting is phosphogypsum from the fertilizer plant.

Contents

The desulfurization gypsum

Desulfurization gypsum has another name as FGD gypsum (flue gas desulfurization gypsum), most of which comes from the power station as a byproduct. It’s chemically nearly identical to natural gypsum from the mine, but with higher purity and fineness. Also with higher moisture (12-17%). It will show different colors from the fuel we used and the dust collect affection we get.

Why make gypsum briquette

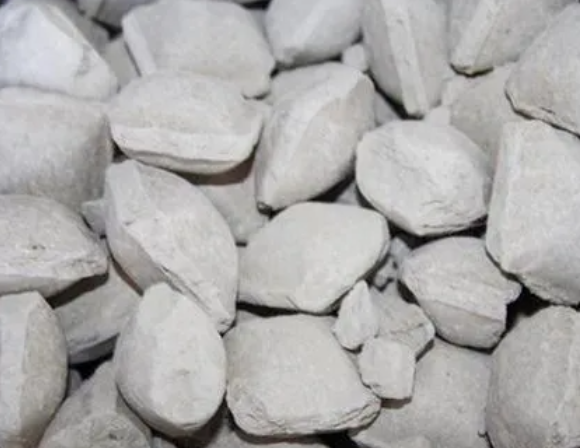

These desulfurization gypsums, with powdery status, is hard for transportation and storage. Dust pollution is also caused by it. Making briquette from this raw material will help to solve these problems.

Those briquettes, after carefully dealt with, can be used to make a lot of product.

Here are some of the examples:

- used to produce cement retarder;

- make gypsum;

- produce gypsum board;

- used to make building plaster;

Turning these waste gypsum to valuable sources could create a way for recycling and make value for us.

The gypsum briquette plant process

Gypsum briquette making follows a very efficient way on briquetting as no binder is needed for this process.

Normally the following equipment are needed to set up the plant.

Dryer, Briquette machine, Compacting machine. Other accessories like conveyors, feeder.

The whole process normally follows this way:

Raw Gypsum ⇒ Feeding ⇒ Drying ⇒ Compacting ⇒ Briquetting ⇒ Finish Briquette

The raw gypsum is first fed in the line with a feeder, then it comes to a dryer(normally we choose rotary dryer) to reduce the moisture, the dried gypsum powder then come to the compacting machine(s) for getting a better standard by output the air between the raw material, these gypsum then is suitable for briquetting and briquetted by a gypsum briquette machine, the output briquette then put in a dryer to reduce its moisture for our standard for storage or selling or something we want to.

Gypsum briquette machine for sale

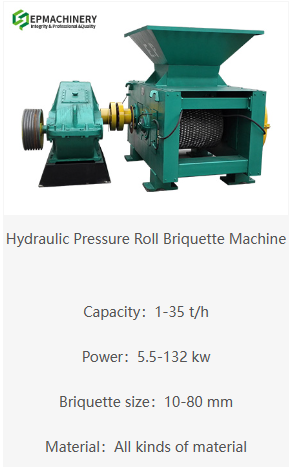

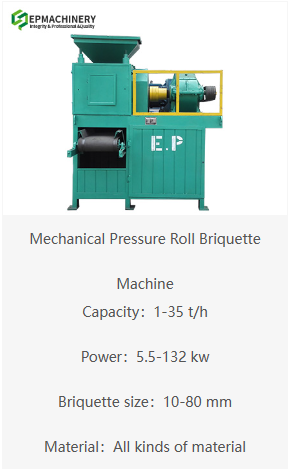

Two types of roller press can be chosen:

a normal type roller briquette press machine can even afford the work. As it’s good performance and a much lower price, it is much popular than the hydraulic type nowadays. It also can equip roller with the same material as the hydraulic type.

Hydraulic type roller briquette press can supply a pressure much bigger than the normal type. By using the hydraulic system, it also increases the service life of the roller and motor by preventing it from blocking. Pressure is easy to adjust with the hydraulic system to meet your demand.