This is our coal briquette machine

What is a coal briquette machine

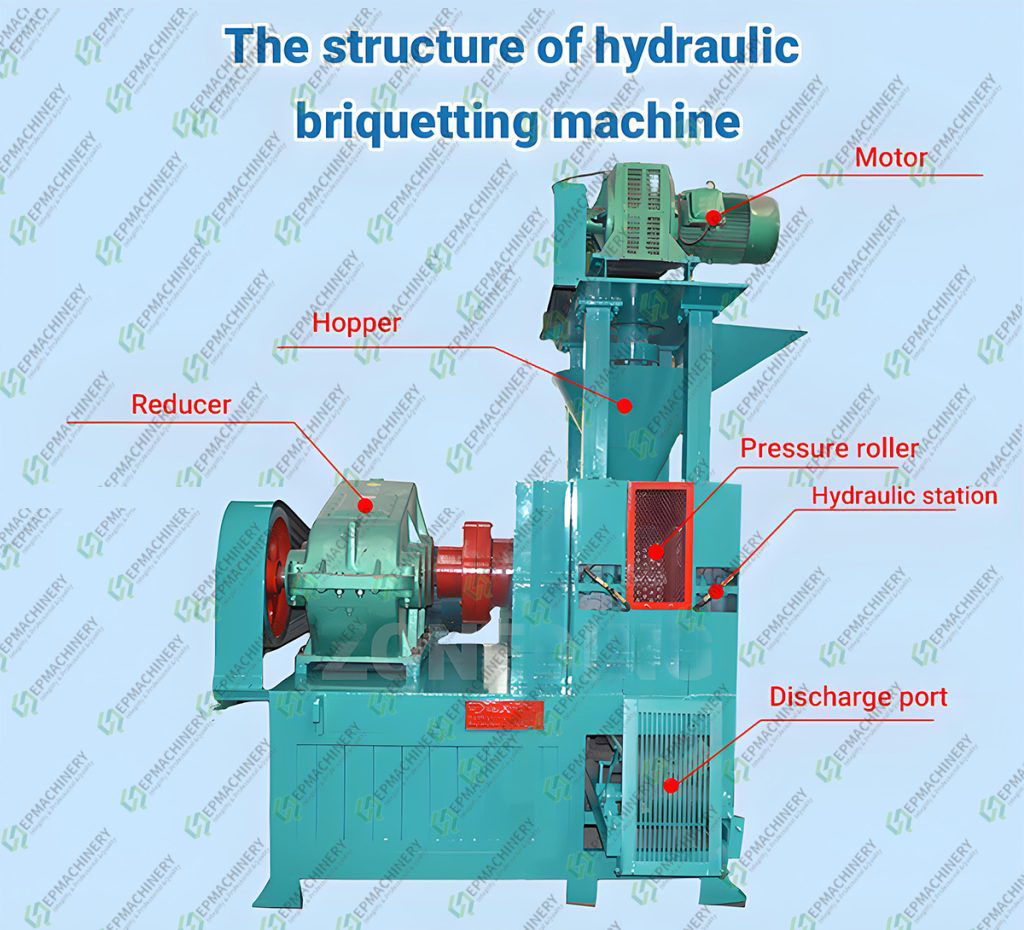

coal briquette press machine, also known as coal ball making machine or coal briquette forming machine. It is a kind of equipment that presses powdered materials into balls. It is mainly used for the forming of various industrial powders. It can press various powders with a particle size of no more than 3mm. It is an ideal equipment for producing clean coal.

Main features of coal pelletizing machine

- High forming pressure, adjustable main engine speed, and equipped with a spiral feeding device.

- Realize quantitative feeding to ensure that the material enters the rollers evenly;

- The transmission part is a motor--triangular belt---reducer---open gear---roller through the main transmission system to ensure stable power transmission;

- The core of the forming part is the roller. When too much material is fed between the two rollers or a metal block enters, the hydraulic protection device can protect the roller from damage.

- The roller skin is made of high-quality alloy forgings, which are quenched as a whole. The hardness can reach HRC60 or above, with high strength, good wear resistance and long service life.

- The forming roller adopts the domestic expansion sleeve mounting layout, which can be disassembled and replaced on site in two to three hours, which is extremely convenient.

- Ball sockets of different standards and shapes can be processed according to user needs. The ball sockets have high smoothness after grinding and are easy to demold.

- coal briquette machine are widely used and can be used for coal powder molding, dry powder molding, desulfurized gypsum molding, coke powder molding, iron filings and various metal ore powder molding. All waste materials in the metallurgical industry and auxiliary materials that need to be put into the furnace require a ball press to complete, such as dust removal ash, pool mud, oxide scale, steel slag, iron concentrate powder, aluminum ash powder, silicon manganese ore powder, etc.

Coal Briquette Machine Rollers and Parts Display

What are the best raw material for making coal briquettes?

The main raw material of the coal briquette machine is coal, but some other auxiliary materials will be added according to specific production needs and uses.

1. Coal Coal is the core raw material. We often use anthracite, bituminous coal and lignite as raw materials.

- 1.1 Anthracite has a high fixed carbon content and low volatile matter. The coal balls made of it are smokeless and have strong firepower when burning. They are often used to make coal balls with high combustion quality requirements, such as home heating.

- 1.2 The volatile matter of bituminous coal is relatively high. There is a certain amount of smoke generated during the combustion process, but its calorific value is also high, which can provide strong heat energy. After being processed by the coal ball making machine, it can be used in industrial boilers and other equipment.

- 1.3 Lignite has high moisture and volatile content and relatively low carbon content, but it has abundant reserves and low price. When making briquettes, other ingredients can be appropriately added to improve its combustion performance.

2. Binder: In order to effectively bond coal particles together to form briquettes, binders are essential materials.

- 2.1 Common binders include clay, bentonite, starch and industrial organic binders.

- 2.2 Clay is a traditional binder with low cost and can increase the strength of briquettes.

- 2.3 Bentonite has good adhesion and water absorption, which can keep the briquettes in good shape and strength after drying.

- 2.4 Starch binders (such as corn starch) are a more environmentally friendly choice. They can be completely decomposed during the combustion process without producing too much harmful substances.

- 2.5 Industrial organic binders have a strong bonding effect and can adapt to different coal qualities and molding requirements.

- 2.6 To learn more about briquettes binder please read:Coal Briquette Binders – Find the Best Binder for Your Briquette Business

3. Combustion aids

- 3.1 Combustion aids are sometimes added to improve the combustion performance of briquettes. Oxidants such as potassium nitrate and potassium permanganate can be used as combustion aids. These combustion aids can provide additional oxygen during the combustion of coal balls, making the coal burn more fully, improving the combustion efficiency, and reducing the black smoke and waste residue produced by incomplete combustion.

4. Desulfurizer

- 4.1 In order to reduce the emission of sulfur dioxide during coal combustion and protect the environment, chemicals desulfurizers are used to make briquettes. Common desulfurizers include limestone (calcium carbonate), calcium hydroxide, etc. During the combustion of coal balls, desulfurizers can react with sulfur elements in coal and fix sulfur in coal slag, thereby reducing sulfur dioxide emissions and meeting environmental protection requirements.

How are coal briquettes made?

How are coal briquettes produced?

The coal mainly goes through the following steps from entering the machine to finally forming into coal balls:

First, the mined raw coal is transported from the coal yard to the factory, and the raw coal is crushed into particles by a crusher.

Then, after the raw coal is crushed, it enters the quantitative feeder, and the adhesive is added to the mixer for sufficient mixing.

Then, the mixed material is forced into the main feed port through the spiral feeding device and enters between the two pairs of ball-socket pressing rollers. The upper and lower rollers rotate in opposite directions, and under a certain pressure, the material is squeezed into pellets.

Finally, after the coal powder is pressed and formed, it is dried, which can be done by drying or sun drying.

Price of coal briquette machine

The price of coal briquette machine varies depending on the model, specification, production capacity and configuration.

Generally speaking, the price of a small coal ball making machine is around tens of thousands of yuan, such as a small raw coal ball press machine, which starts at about 25,900 yuan per unit; while the price of a large coal ball making machine may be as high as hundreds of thousands or even millions of yuan.

If you are interested in the briquette business, or you want to expand your briquette business, please contact us. We have rich experience in coal ball plant projects and a professional coal ball knowledge team.

Kenya 15-20 t/h coal briquette plant

This project is a coal briquette plant project in Kenya

Designed coal briquette production capacity: 15-20t/h

Raw materials: coal powder + lignite